Crushing Technologies - thyssenkrupp Polysius

The mammut® crusher is uncomplicated and compact in design, rugged in its construction, extremely powerful and completely safe in operation and with a minimum maintenance

More

Crushing Limestone Impact Jaw Crushers RUBBLE MASTER

Meet your spec with multiple crusher settings and an on-board screening plant and return conveyor (closed circuit impact crusher). In many cases, crushing limestone does not

More

Design of a Material Handling Equipment: Belt

2014.1.16 This paper discusses the design calculations and considerations of belt conveyor system for limestone using 3 rolls

More

Crushing Plant Design and Layout Considerations - 911 Metallurgist

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design

More

11.19.2 Crushed Stone Processing and Pulverized Mineral Processing

primary crusher. Jaw, impactor, or gyratory crushers are usually used for initial reduction. The crusher product, normally 7.5 to 30 centimeters (3 to 12 inches) in diameter, and

More

Limestone Mills Limestone Crushers Pulverizers

Williams Crusher’s limestone mills and Pulverizers offer solutions for various size-reduction applications. We design manufacture the most durable efficient limestone crushing machines on the market. Contact

More

Crusher - Wikipedia

With the rapid development of mining technology, the cone crusher can be divided into four types: compound cone crusher, spring cone crusher, hydraulic cone crusher and

More

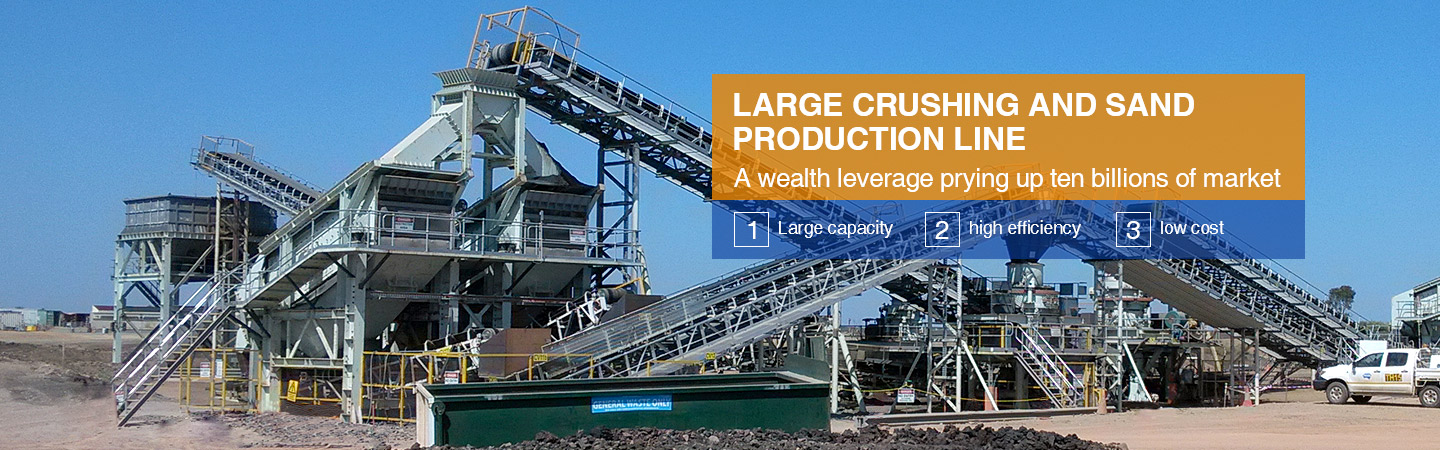

Limestone Belt Conveyor System used in Crushing Plant in China

Limestone belt conveyor system used in crushing plant for sand making in China Location: Zuny, Guizhou, China End User: Zunyi XXX Building Materials Co., Ltd Equipment:

More

Review of the in-pit crushing and conveying (IPCC ... - ResearchGate

In 1956, the first mobile crusher was installed in a limestone quarry in Hover, West Germany. The crusher enabled the quarry operator to take advantage of continuous belt

More

Limestone Belt Conveyor System used in Crushing Plant in China

Limestone belt conveyor system used in crushing plant for sand making in China. Location: Zuny, Guizhou, China. End User: Zunyi XXX Building Materials Co., Ltd. Equipment: conveyors belt width 1200mm, 800mm, 650mm with covers . Applications: Crushed limestone conveying for manufacturing sand.

More

Limestone Crusher, Small Mobile Crusher - VYKIN Crushers

Small Mobile Limestone Crushers For Sale $1.8K/mo — Versatile, Easy to Use, Setup Move. Our Limestone Crushers Are Ideal, Affordable Solutions For A Wide Range Of Job Applications. Profitably Crush On-Site, Eliminate Disposal Costs Use Base Aggregate for Huge Savings. $ 98,500.00. Category Crushers Tag Limestone Crusher.

More

December 3, 2021 Fatality - Final Report Mine Safety and Health ...

2021.12.3 FAI-6915440-1 UNITED STATES DEPARTMENT OF LABOR MINE SAFETY AND HEALTH ADMINISTRATION REPORT OF INVESTIGATION Surface (Limestone) Fatal Powered Haulage Accident December 3, 2021 Brooksville Quarry CEMEX Construction Materials Florida, ... consisting of a portable crusher and belt

More

cement plant limestone crusher details - LinkedIn

2023.8.10 Limestone is transported to the crusher via large haul trucks or conveyors. Crushing Process: Limestone is fed into the crusher's hopper or directly into the crushing chamber, depending on the ...

More

Review of the in-pit crushing and conveying (IPCC

In 1956, the first mobile crusher was installed in a limestone quarry in Hover, West Germany. The crusher enabled the quarry operator to take advantage of continuous belt conveyor haulage and ...

More

11.19.2 Crushed Stone Processing and Pulverized Mineral Processing

Due to the specialized characteristics of the mineral products and the markets for these products, pulverized mineral processing plants have production rates that are less than 5% of the production capacities of conventional crushed stone plants. Two alternative processing systems for pulverized minerals are summarized in Figure 11-19.2-2.

More

(PDF) Mining Activities, Cement Production Process and

2022.7.4 It is a chain conveyor which conveys limestone from the dump hopper into the double impact rotary crusher. When switched on, it starts moving 15 minutes later than the primary crusher

More

Crushing Plant Design and Layout Considerations - 911 Metallurgist

• Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001) • More attention is being paid to the impact on crushing circuit design caused by variations

More

Modern Technological Applications for Limestone Mining

2021.7.15 Rippers can be used for limestone mining as limestone is a ‘rippable’ sedimentary rock (refer to Sect. 3.1.1) Using rippers in small mines or for a group consisting of more than one mine is economical and productive. Instantaneous blasting or blasting with delay detonators in mines are executed in circuits.

More

Limestone crushing Plant Conveyors - IndiaMART

HS Engineers manufacture best quality Limestone crusher plant trough belt conveyors. Our Conveyor Belt is abrasion resistant. Pulleys: 10 mm thick rubber lagged MS Pulley Belt: M24 grade rubber. View Complete Details. Get Latest Price Request a

More

Determination of semi-mobile in-pit crushing and conveying

2021.2.12 In-pit crushing and conveying (IPCC) is a material handling system with a feed system, crusher, conveyors and discharge systems as shown in Fig. 1. It involves in-pit crushing of materials. The use of IPCC is justified by its benefits such as reduced operational costs due to minimal trucks usage, high production output and reduced gas

More

De-dusting for a mobile crusher - Cement Lime Gypsum - ZKG

Air pollution control „Made in Germany“. Limestone is mined in the quarry. The de-dusting plant itself is designed for an air volume of 97500 Bm³/h and can be shipped in normal containers. The filter was built by Münstermann in Germany and shipped in screwable segments in containers to the USA. Welding on site is not necessary.

More

Rock Crusher Machines Pulverizers Williams Crusher

Contact Williams Crusher. Contact us today to discuss your rock crushing application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher or locate an agent near

More

The working principle of limestone crusher - News of Joyal Crusher

2021.1.28 Feeding Conveyor Complete Crushing Plant. Contact Us. joyal@crusherinc +86-21-68763311 +86-21-68763366; The working principle of limestone crusher (No Ratings Yet) Loading... Date: 2021-01-28. Joyal limestone crusher is a kind of equipment that crushes materials in the form of impact, also called hammer

More

LIMESTONE CTC Dubai Commodities Trading Company LLC

CTC is a major supplier of high-grade limestone to international consumers. With an access to a large volume of deposits. CTC is handling large export orders to various countries. Low silica content makes CTC limestone suitable for the steel industry. Limestone consignments are put through crushers and screening plants. Conveyor system loading ...

More

Mobile, Fixed Plant Screen and Crusher Belts - All State Conveyors

Features of Mobile Crusher Conveyor Belt. These belts can be made from M, DIN-Y, N and XCG rubber compounds for mobile crushers, screens and radial stackers and may be supplied with either natural flat rubber, C5 ~ C25, multi-V or other more complex profiles. We also carry various sized belts for these systems from 300mm through to 2200mm or ...

More

crusher for limestone 250 tph - LinkedIn

2023.10.17 Meeting the Challenge: A 250 TPH Limestone Crusher Solution Limestone, a versatile and widely used rock, ... cost of a conveyor belt systems for mining Oct 13, 2023

More

Energy gained by downhill limestone transport - Cement Lime

Therefore, reliable and cost-efficient technical solutions are a necessity for the success of every cement plant. In the past, limestone was often transported by truck which meant both high cost and environmental pollution. Today, continuous conveyors are acknowledged world-wide as a cost-efficient alternative [1].

More

Crushed Limestone - SBM Mill Crusher

2023.5.4 This type of screen has a vibrating screen deck that rapidly shakes to separate the limestone into various sizes. If any material is too big to pass through the screen, it gets sent back to the crusher for further crushing. Conveyor Belt . Once the limestone is crushed and screened, it is transported to a storage facility using a

More